We conceptualize your ideas and develop competitive designs to build better products at lower cost.

With 30 years of legacy in providing engineering design solution for diversified Industry verticals, we at Moldwell design & develop products creatively & intuitively using Industry leading software’s like Pro E, Solid Works. etc. Synergizing our engineering and manufacturing strengths with human centred approach, we conceptualize your ideas and develop competitive designs that consider aesthetics, usability, and ergonomics. Our in-house experts with vast Industrial knowledge help you to achieve your overall product cost plan and business objectives.

Empowered with sophisticated technology and efficient personnel, we assist you to develop innovative products that increase your productivity, thereby your profits and above all place you ahead of competition. As our customer can foresee the end component being reflected in the product design itself he can do any alterations required at the design stage itself besides going for volume production.

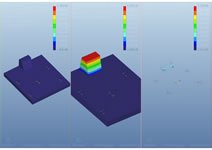

We validate and troubleshoot the potential design problems against given criteria and get things done right the very first time.

A significant process in product modeling, avoids costly rework thereby allowing you get things done right the very first time. This process has major impact on a company’s bottom line. Companies are now on the look out for innovative product with improved processes at competitive price. Moldwell addresses their needs absolutely by validating the design against given criteria. Technocrats at Moldwell make the best use of advanced technologies and software such as Moldflow and Moldex for product validation.

By performing this product validation process we troubleshoot the potential design problems and confirm to the products manufacturing feasibility, durability and enhanced productivity. We ensure that the new product design exactly assembles with other parts.

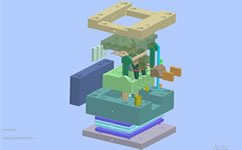

With complete in-house facilities and competent mold makers, we develop molds that are precise, and durable.

Moldwell is into manufacturing of Molds for the past 30 Yrs. Being in this domain since 1981, we specialise in building the most complex molds precisely. We make Molds with

Gaining experience by catering to the needs of diverse industry including Textile / Automobile / Pump / Appliances and Lighting our competent mold makers know the key requirement of each sector and are capable of producing the high quality mold in short lead time.

With complete in-house capabilities, we develop mission critical complex molds that meet client’s purpose to their utmost satisfaction. Our Molds are noted for their features such as superior strength, durability & high performance standards. We also offer customisation as per the specifications detailed by our clients. We continually put relentless efforts to excel by ensuring information accuracy from engineering to production.

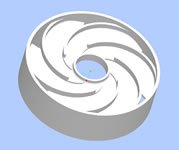

We mold complex parts meticulously from high performance engineering plastics to maximize efficiencies, save production time and costs.

Having about 70 machines with a capacity range between 25 T - 300 T, we mold complex parts meticulously as per our client’s specifications. Our in-depth experience with the materials and processes help us meet the geometry and tolerances that your product demands. By paying attention even to a very small feature on a normal sized part, we maximize efficiencies, save production time, and lower costs.

Our ability to manufacture these parts consistently and to deliver them on time is our strength. By strictly following the systems & procedures, we will trace the various details related to the particular Mold from its entry stage. We produce tight tolerance molds from high performance engineering plastics including Nylon (Filled and unfilled grades), polycarbonates, ABS (Filled and unfilled grades), PES and PEEK. Our core expertise is to develop plastic parts from a variety of materials that suits the application of your product.

Deploying standard quality systems, we meet client requirements and make sure that consistency is maintained throughout in all supplies.

We are ISO certified company complying with ISO 9001 quality standard. By strictly following the system we control every process from design to production. Having separate QA departments and by following FIFO procedures we ensure that every customer gets the best product and service. Every employee at our work makes certain that customer satisfaction is maintained in term of quality and repeatability in supplies. We have received appreciation certificates from our customer for the quality work delivered to them on time. Separate testing departments at our facility test that our product output meets the agreed criteria. With streamlined quality checking processes at our premises, we at Moldwell are committed to achieve customer satisfaction in terms of quality, delivery and service.